The Porsche Carrera C4 is one of the hottest highway bombers on the road. With its all-wheel drive, the Porsche is always ready to duel – road conditions be damned. As destructive as the C4 may be, the crew at BEGI (Bell Engineering Group, lnc.) couldn't wait to get their hands on it.

BEGI, once the U.S. distributor for the haltech programmable engine control computer under the Cartech name, definitely knows how to set up custom fuel injection systems. The company's latest product line for turbo systems, called BEGI! However, it has a different philosophy: retaining the standard fuel injection computer on turbo conversions to make it easier to comply with emissions regulations in all 50 states. BEG I has achieved excellent results in turbocharging the Acura NSX, the Ford Mustang, the Mazda Miata and the Porsche Carrera 4 presented here. This was achieved by maintaining engine management under all conditions while manipulating fuel pressure under turbocharging conditions via a dedicated Cartech variable boost rate fuel pressure regulator to produce the correct air-fuel ratio.

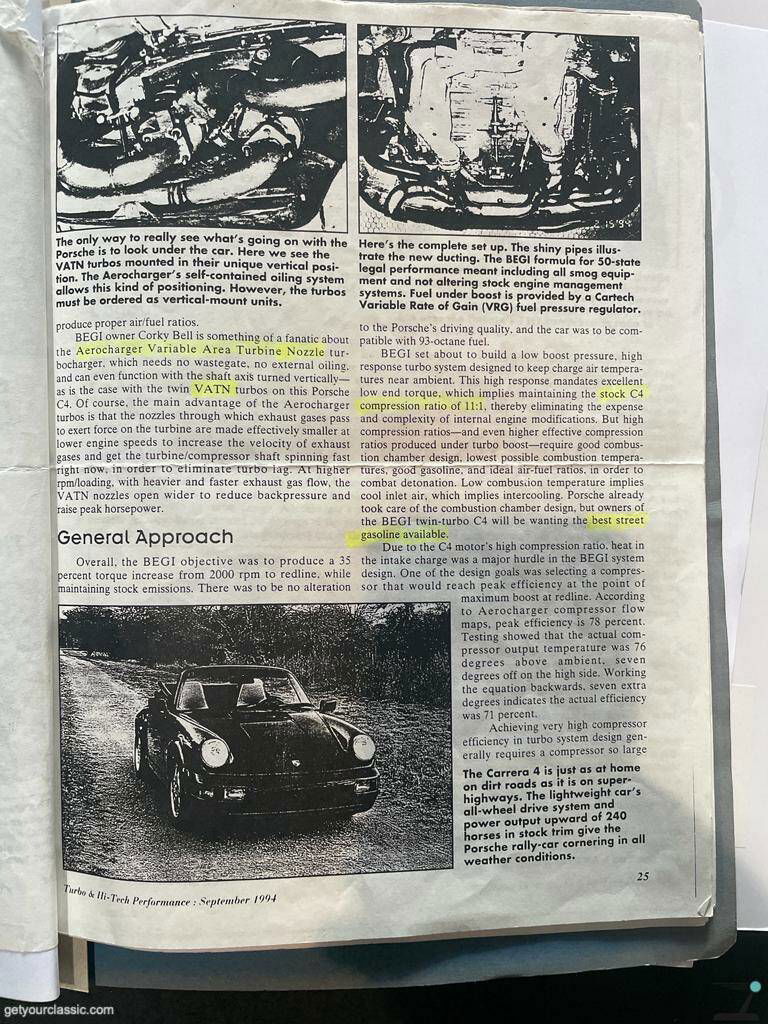

BEGI owner Corky Bell is something of a fan of the Aerocharger turbocharger with variable turbine nozzle, which requires no wastegate or external oil supply and can even function with the shaft axis rotated vertically, like this Porsche's two VA TN turbos C4 is the case. Of course, the main advantage of the Aerocharger turbos is that the nozzles through which the exhaust gases flow to apply power to the turbine are effectively reduced in size at lower engine speeds to increase the speed of the exhaust gases, instantly spinning the turbine/compressor shaft quickly to eliminate the turbo lag. At higher speeds/loads and a stronger and faster exhaust flow, the VA TN nozzles open wider to reduce back pressure and increase peak power.

General approach

Overall, BEGI's goal was to increase torque by 35 percent from 2000 rpm to the speed limit while maintaining series emissions. The driving characteristics of the Porsche should not be changed and the vehicle should be able to run on 93 octane fuel.

BEGI set out to develop a low boost, high response turbo system that keeps the charge air temperature close to ambient temperature. This high responsiveness requires excellent low-end torque, which requires maintaining the original C4 compression ratio of 11:1, eliminating the cost and complexity of internal engine modifications. But high compression ratios – and even higher effective compression ratios produced under turbocharging – require good combustion chamber design, the lowest possible combustion temperatures, good gasoline and an ideal air-fuel ratio to combat detonation. Low Combus, Ion temperatures mean cool intake air, i.e. charge air cooling. Porsche has already taken care of the combustion chamber design, but owners of the BEGI twin-turbo C4 will want the best road gasoline available.

Due to the high compression ratio of the C4 engine, heat in the intake tract was a major hurdle in the design of the BEGI system. One of the design goals was to select a supercharger that reached its maximum efficiency at the point of maximum boost pressure at the red line. According to the Aerocharger compressor maps, the peak efficiency is 78 percent. The tests showed that the actual compressor outlet temperature was 76 degrees above ambient, seven degrees too high. If you reverse the equation, the seven additional degrees result in an actual efficiency of 71 percent.

To achieve very high compressor efficiency in the design of turbo systems, the compressor must generally be large enough to be sluggish at low speeds. However, with the V ATN design, the superchargers were able to be driven sufficiently to achieve a boost pressure of five psi at 1400 rpm! However, when testing the finished design, an unforeseen problem emerged: When the response was set to maximum, the turbos reacted so sensitively to small throttle valve increases that unwanted boost pressure surges had to be eliminated by increasing the minimum outlet area of the VA TN turbos.

If you are thinking about installing a BEGI C4 system and increasing boost pressure with race fuel, you should know that boost pressure on a system like this is limited not only by detonation considerations, but also by fuel pressure. The Cartech regulator increases fuel pressure under boost at a rate of at least four to seven psi of fuel pressure increase per pound of boost to prevent leaning. Given the limitations of the injectors and fuel pump, fuel pressure typically cannot rise much above 90 psi, leaving about 40 to 50 pounds of excess pressure to work with. Therefore, boost pressure limits of five to 10 psi overall are essential (perhaps even slightly less to allow for margin of error).

construction

BEGI mounted two Aerochargers with the shafts on a vertical plane, both on the driver's side of the vehicle. Each turbo compressor feeds into a single intercooler. The only outlet of the intercooler flows into the Bosch air mass sensor. Both turbos flow directly into the catalytic converter and then into the silencer. The pipes above are short enough to heat the turbos, catalytic converter and lambda sensor well.

Turbos

The variable cross-section turbine nozzle (VA TN), as used by BEGI on the C4, solves the problem of turbo lag with an ingenious approach to turbo design. Manufacturer Aerodyne first used the variable vane turbocharger concept in the late 1970s and produced one of the first commercially available units in the early 1980s. The device uses a relatively conventional – albeit extremely efficient – compressor section. However, the turbine part is revolutionary. The exhaust gases, flowing at high speed around the circumference of the turbine housing, are directed to the turbine wheel – not through a single fixed-size opening like a traditional turbocharger, but through a continuous slot around the entire circumference of the turbine housing. A series of foldable guide vanes are arranged in the slot radially around the turbine wheel. When the vanes point directly, that is, almost toward the center of the turbine wheel, the resistance to the flow of exhaust gases is low and the exhaust gases impinge on the turbine wheel at relatively low speeds with little resistance or back pressure. However, when the blades rotate so that they are almost abutting each other, a flow is created that is almost tangential to the circumference of the turbine wheel. The exhaust gases must be accelerated to very high speeds as they flow through the narrow path between the blades.

Even at low engine throughput, the exhaust gases can be accelerated quickly to generate a lot of boost pressure at low engine speeds.

Interestingly, the Aerocharger is in fact its own “wastegate”. An actuator and the aerocharger turn a wheel that simultaneously changes the angle of all the blades at once. The closed blades act like a very small air opening at low engine speeds, gradually opening at higher speeds to control the turbine speed. The actuator is adjustable similar to some wastegate actuators and is related to the boost pressure like a wastegate.

Aerodyne's variable turbocharger has another unique feature for a turbocharger: the oil system is self-contained. Every 20,000 miles, add 100 ml of synthetic oil to the unit that does not share oil with the vehicle engine. In other words, the Aerocharger unit has no oil lines! The oil wick can be adjusted during manufacture so that it can be installed vertically.

Aerocharger supercharger sections are available in seven levels from 70 to 290 hp. BEGI uses two 220 hp units for the C4.

Exhaust gases from the two Aerochargers are routed through the Borla dual-path stainless steel alloy muffler with eight square inches of flow area.

intercooling

On the Porsche C4. For reasons of space, sufficient intercooling with an efficiency of 80 percent and a pressure loss of 0.5 psi was possible. The intercooler is located behind the rear wheel on the passenger side. However, the hoped-for intercooler efficiency of 90 percent proved difficult to achieve. The charge air temperature exiting the intercooler was 21 degrees above ambient, suggesting that actual efficiency was closer to 71 percent. The reason for this was never determined by BEGI, although suspicion was based on the large thickness of the core material. In retrospect. BEG I decided that thick cores were unavoidable as significant pressure losses had to be avoided.

fuel supply

The Cartech Variable Rate of Gain (VRG) fuel regulator is located downstream of the stock Bosch fuel pressure regulator. It has no effect during natural aspiration operation and allows fuel to flow freely into the fuel return line. Under boost conditions, the distributor referenced VRG fuel regulator progressively limits fuel return to achieve an increasing rate of fuel pressure rise up to a maximum of 85 psi of fuel at t1vs psi of boost. BEGI left the Bosch mass air flow sensor in its original position to avoid delaying the air-fuel ratio, as the system was designed so that the turbos were a certain distance from the meter. Bell felt that five psi would not place undue stress on the flow meter housing. The fear that the exhaust gases from the crankcase ventilation could cause problems with the flow meter and therefore a condensation filter would be required turned out to be unfounded.

performance

On the road the thrill is precise

like a C4. just more. If you've read the reviews of the C2 and C4, you'll know that the C2 is a little quicker – except when all-wheel drive comes into play, like starting from a stop and so on. The BEGI C4 is noticeably faster than both. BEGI claims the C4 is the sharpest five-horsepower turbo system we've ever driven. It feels more like a 10 horsepower car. The performance is estimated by BEGI at 320 to 330 horsepower. BEGI's approach to improving the C4's power-to-weight ratio was to preserve as much as possible the 3.6-liter engine with 240 hp and 240 lbs-ft of torque, twin-plug configuration and an 11:1 compression ratio. With the VATN turbos, the engine achieves high performance up to 8000 rpm, which, according to BEGL, results in a 0-60 time of around 4.6 seconds, compared to 5.5 seconds in stock condition. The Aerocharger V ATN concept eliminates any feeling of hesitation, followed by the power increase of some conventional turbos, including many Porsche factory turbos!